AND

AND  2000

20001995  AND

AND  2000

2000

THE FLAMBEAU MINE

Casey & Jane Jones

INTRODUCTION

HISTORY

Many years elapsed between this early work and Kennecott’s initial interest in the Lake Superior region starting in the 1950's. This interest was based in part on the supposition that the Canadian Precambrian Shield, which to the north in Manitoba and Ontario contains many massive sulfide deposits, that such mineralization should continue south in Minnesota, Michigan and Wisconsin. In 1954 George Moerlien began prospecting in Wisconsin and Michigan for Kennecott’s wholly owned subsidiary Bear Creek Mining. While in Madison, that same year, Moerlien was shown Hotchkiss’s rock specimens and information. One specimen was particularly exciting in that it assayed 0.7% copper. The report by Hotchkiss on this specimen stated that it came from a well dug near the old school house, south of Ladysmith.

Moerlien traveled to the school house and searched the area, but while no outcrop was visible, azurite and malachite fragments from the old well were found.

It was decided that since airborne electromagnetic (AEM) surveys were being flown over parts of Minnesota and Wisconsin that some smaller targets should also be flown. The school house prospect was selected as one of these. No anomalies were detected, however, enthusiasm continued for the possibility of deep massive sulfide mineralization.

W.F. Read and Russell C. Babcock of Lawrence University continued geological mapping through the late 1950's, generating data from which the next stages of exploration were based. The period between 1960 and 1965 was a quite one since Kennecott went west looking for copper porphyry deposits.

Kennecott reentered Wisconsin in the mid-1960's, at about the same time Carl E. Dutton of the United States Geological Survey began conducting a library research program where by all the notes, rock and mineral specimens collected since 1915 were reexamined and compiled. Dutton with Reta Bradly eventually organized all this early data into a comprehensive geological map of Wisconsin, which was published in 1970.

Great Lakes Exploration, a wholly owned Kennecott subsidiary, with Jack Phillips as exploration geologist, reentered Wisconsin in 1965 to continue the massive sulfide program due in part to an increase in depth penetration of the AEM system.

Jack Phillips spotted the same sample Moerlien had seen which was now sitting on Dutton’s desk. Based on this sample plus other weakly mineralized outcrops found in western Rusk County and reviewing the extensive data generated by Read and Babcock in the 1950's, Phillips convinced Great Lakes Exploration to fly a large area of the county. This area included the school house in the southeast corner, the Flambeau river on the east side, and the Blue Hills located in the northwest corner.

E.H. Eisenbrey supervised the AEM program that resulted in a strong anomaly on the eastern most line on the east bank of the Flambeau River, just south of Ladysmith. Amazingly had the eastern line been flown one line to the west, the Flambeau deposit would not have been discovered. In 1967 Eisenbrey authorized two additional short lines to be flown from the river east to highway 27, a distance of 1 mile. These lines eventually resulted in the drill discovery of the Flambeau deposit.

In the spring of 1968, an extensive exploratory core drilling program began in Rusk County and on November 6th of that year the Flambeau deposit was discovered. Core pulled from that hole showed 48 feet of massive supergene enriched chalcocite that averaged 9.25% Cu. Drilling to define the deposit, along with environmental studies and public hearings continued through 1976.

From 1977 to 1985 the project remained dormant. In 1986 Kennecott reopened the Flambeau project since copper metal price forecasts were optimistic. Progress towards actual construction and mining involved numerous public hearings, reviews, and permit applications from 1987 to 1991.

Ultimately due to the dedication and commitment of the Flambeau Mining Co., a wholly owned subsidiary of Kennecott Minerals, permits were granted in June 1991. Ground was broken on Wisconsin’s first sulfide metal mine to operate under Wisconsin’s new mining laws in 1992 and on June 28, 1993, the first crushed copper ore was shipped via rail out of state for processing.

Since 1993 the mine has successfully operated without any violations, citations or complaints to the present day. This is a truly outstanding accomplishment since the mine is within 140 feet of the Flambeau River, 500 feet of Highway 27, within 1000 feet of private residences and 2500 feet of a liberal arts college, Rusk County hospital and nursing home.

COLLECTING

HISTORY

The

collecting history like so many operating mines in the past really begins with

the geologists on site or the miner

picking up a pretty rock. In the case of the Flambeau it was

a lot one and a little of the other. The visitors center needed specimens

from the mine to put on display for the

interested public so mine

geologists collected specimens of

azurite, malachite, native copper and chalcocite.

It was these very specimens that encouraged the authors to seek a recovery

contract with the Flambeau Mining Company.

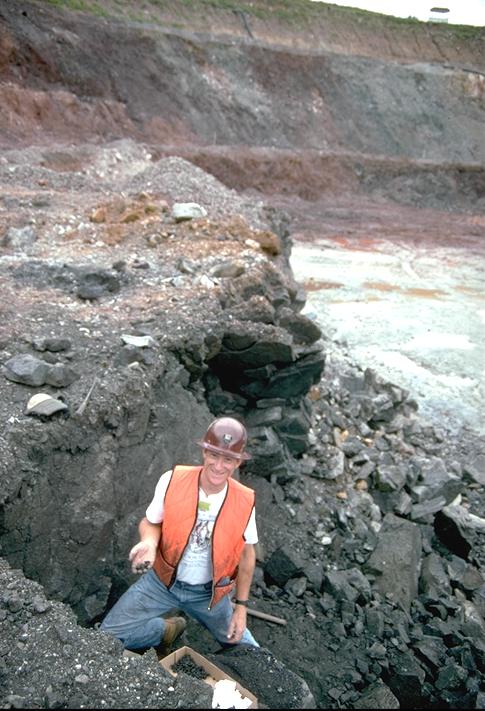

The

first day collecting at the

Flambeau was very much different than the underground environment that had so

much been a part of our collecting experience. We went to work immediately

at an area where the ore body contacts the quartz- sericite schist or

siliceous chert. We were quickly rewarded with a few reniform to sub-euhedral

crystallized chalcocite specimens. All of these first few pieces were of the

typical black to steely-gray color so characteristic of chalcocite.

Two

days of sporadic finds of this kind of material while exciting were just wetting

our appetite. We really felt that with the kind of specimens that we had up to

this point found and the specimens we had seen at the visitors center and in the

administrative offices that the good ones were just a few more inches from our

last pick hammer blow. On June 30th 1994 our intuition was proved

right. A small pocket, beneath a ledge formed when a large block of chalcocite

ore was removed, contained 5 chalcocites that rivaled anything we could have

realistically imagined. Having personally handled thousands of specimens over many years,

never had I held such a spectacular specimen, let alone a chalcocite.

This

led us to immediately name this void the First Pocket

Photo by Jane Jones

Photo by Jane Jones

Thankfully this pocket led us directly to, and on the same

day, to the watercourse pocket, which was a few inches into the face of the work

area where the First Pocket was. The Watercourse pocket as the name implies had

water running in it, the chalcocites from this void all had a gold patina which

after time turn violet-purple. The crystallization was not quite up to the level

of the crystals of the first pocket, but confidence reined supreme.

The

next pocket to be discovered was the Sunrise Pocket. It was a long interval

between this discovery and the past success earlier in July.

To

have some muck cleared from this area we needed Joe the excavator operator. So

as not to impede production he could on his way to his mucking spot take a

couple of cleanup swipes at our promising area.

Of

course starting time is as soon as there is just enough light to see.

Joe

expertly maneuvered the shovel of the excavator to get as much of the muck away

from the corner that looked the most promising. Still I was left with the need

to hand muck approximately three or four yards of sulfide ore.

Just

as the sun was peeking over the rim of the pit, the outline of an in situ pocket

was revealing its self.

The

Sunrise Pocket, October 10th, 1994. This pocket was

in a corner formed by the 1010 level bench and the footwall bench.

Slowly

brushing away the loose damp bornite sand started revealing gleaming bright

metallic golden crystals. They were packed in with just enough space between

specimens to facilitate one by one removal. Laying on my stomach I slowly

worked the pieces out using the sand as a cushion for the chalcocites

when needed. Small broken shards of quartz-sericite schist and small

chalcopyrite casts after calcite, that looked like hundreds of tiny ice-cream

cones made up the pocket debris.

The chalcocites that came from this pocket were unusual in that they had bornite after chalcocites associated with them. Also the sizes of the crystals were almost unbelievable. One crystal group the "Flambeau Chief", with most prominent crystal coming in at almost 4cm across.

It

was a long cold winter between the Sunrise Pocket and the next significant

pocket that was to be discovered by us. Meanwhile while attending the Tucson

Show in 1995, the drill rig operator broke into what could be considered a small

chamber measuring aprox. 6 feet long by 3 feet wide and unknown depth before

pinching out. The location is documented at 401.5 - 1000 level, hanging wall

contact. Named the Drill Pocket for the fact that the drill rig had punched into

the top of the void. The Drill

Pocket, contained what we still believe as the finest chalcocites in the world.

Unfortunately since we were not there to collect the specimens before mining

needed to proceed all of these specimens were either heavily damaged or lost

forever due to the close proximity of high explosives going off. Very few

specimens

survived

unscathed. We still to this day dream of what this void could have yielded if it

had been carefully collected.

The

next significant pocket for us was the

Fog

Pocket, 409.6.2 - 1000 level,

March 30th,1995. This small pocket was encountered one cold sunny morning,

temperature about 28 degrees F, while scouting the exposed 1000 bench on the

footwall contact. While probing for loose ground a small avalanche of rock and

ore debris fell away at chest high

level causing a quick retreat backwards. Excitement grew even as I did the

Flambeau two step. Quickly recovering my balance and homing in on the new muck

pile at my feet I saw beautiful delicate small perfectly shaped

"stopsign"

crystals of golden-violet chalcocite scattered atop the broken muck.

The

two dozen or so of these specimens were thumbnails, and quickly wrapped.

Tracing

the route up from which these specimens came from revealed a small opening

densely packed with crystallized chalcocite, trending up to the crest of the

bench, just over head. Working around this pocket created more muck upon which

to stage the ultimate removal of the chalcocites contained within. Recoveries of

these were particularly difficult do, do to the cold. Wearing fingerless gloves

and using only small screwdrivers and bare fingers to extract the beauties.

Crouching as much for warmth as getting positioned closely enough to the pocket

opening. Every time a breath was exhaled a transient but none the less annoying

fog bank would form, …well Fog Pocket. This pocket produced a dozen

outstanding specimens. The sharp

edges

and delicate habit of these crystals were never found again.

Next

comes the Lucky Friday Pocket, naming this one was easy, Friday, October 13th.

This

one was a bitter sweet experience. By this time we were living full time in

Ladysmith and onsite every day watching every load of ore and waste rock that

Joe lifted out of the broken and shattered

blast pile . Along with checking almost all the drill holes that were

drilled by drill tech Randy Ralston and crew. On this day there was guarded

optimism. The day before while the drilling the blast pattern for this shot, one

hole encountered a good sized void at 7.5 feet. This hole was left unloaded of

explosives and as many burlap bags we could stuff down the hole was placed.

Credit here must be made to the blasting crew for their expertise and

in particular to Ames Construction project manager Bob Donalson for the creative

basting techniques used to help minimize destruction of specimens and yet

"pull the round". Late in the day after the shot on the 12th

,scouting this blasted zone broken loose crystals were recovered. We had Joe

position the excavator, and he directed

the haul trucks in such a way as to be able to dig perpendicular to the strike

of the ore body, taking small slices from the area were we expected to find the

burlap bags. Late in the afternoon with heavy clouds threatening snow,

the bucket swept past where the hanging wall contact was exposed, and big

crystals started sliding out and down the soft pocket muck. The feeling was one

of elation yet concern that nothing would survive . No burlap was yet visible.

There was 10 feet of heavy broken ore on top of this exposure.

Joe

expertly worked the cap off the area and the burlap bags became visible, muck

was removed down to the last bag . With

just an hour of light left expedient removal of the best specimens was of the

utmost concern. Incredibly many specimens survived the harsh treatment of

blasting, mucking, and rushed recovery.

Once again the nature of these chalcocites was completely different from any we had seen. The crystals ranged from thick disc-like sub parallel stacking to rarer heavy thick penetration orthorhombic x-twins and the classic perfect "stopsign" sixling twins. Predominate color was golden, darkening to brass, violet, purple, blue and gray, depending on the angle of light and viewing. There were a very few specimens that had a non-iridescent coating of matte blue bornite.

The

Quick Pocket needs a mention because the location of the pocket was unusual.

On

the hanging wall contact but far from the more productive west end. This pockets

location was 415.2 - 980 level, recovered on May 20th, 1996. Digging

while drilling

was

taking place just above the pocket area necessitated the more than usual constant

monitoring of loose ground. The drilled pattern was to be shot regardless of

mineral specimen concerns, the main

ramp into the pit was at stake. So quick recovery methods were used. Quick

Pocket.

The chalcocites from here are less well developed and are tending to be replaced by bornite. Crystals ranged up to 6cm.

The Rocket Pocket. Located at 401.3 - 970 level.

This was to be the last significant

pocket encountered. It did not come quickly rather it was drawn out over almost

a weeks time. Beginning with the start of drilling the pre- split holes on the

970 level at 401.3, on the far west end of the pit. These holes were drilled for

the step outs which were planned every 30 feet or three levels. Consequently

these holes were drilled to a depth of 30 feet, every three feet, versus the

normal blast hole of ten feet.

Starting

on Friday the 9th drilling

progressed smoothly starting on the far south footwall side, perpendicular to

the orebody ,moving towards the far side of the north hanging wall side of the

pit. Trouble drilling began

when

the first hole closest to the hanging wall contact zone collapsed and the drill

steel became hopelessly stuck. One new hole was begun near this bad hole and at

a depth of about 2 feet the drill steel dropped through 4 feet of void before

biting into hard ground again. When steel dropped our hopes soared!

The

decision was made to pull out of this hole before the steel became stuck as the

condition of this hole was rapidly deteriating. After pulling the steel from

this hole it was evident that it would not be able to be used to set explosives,

a 3 foot section of 2 inch PVC pipe was pounded in as far as it

could go into the broken and collapsing hole.

The next hole to the north was

barely competent enough to load. The rest of the holes to the north held up well

and were not a problem. To drill the presplits had taken Friday, Monday, and

Tuesday. That was one long weekend. The regular blast pattern was drilled out

and loaded along with the presplit holes with explosives on Wednesday.

The next hole to the north was

barely competent enough to load. The rest of the holes to the north held up well

and were not a problem. To drill the presplits had taken Friday, Monday, and

Tuesday. That was one long weekend. The regular blast pattern was drilled out

and loaded along with the presplit holes with explosives on Wednesday.

The

blast countdown commenced late in the day on Wednesday. Just as the words

"fire in the hole" finished leaving Bobs mouth, the ground erupted in

the familiar staccato of timed charges going off. The PVC pipe had become

airborne, shooting almost straight up trailing smoke and dust . There was an

easy name for a pocket.

Onsite

and ready to go at first light, tools at the ready, this had to be a good one.

One,

a void was there, two, it was up against hard face, and three we were due.

Again

Joe set up to mine away the hanging wall contact area in the most productive and

merciful (to the specimens) way.

At about 10:00AM the outline of a large cavity was quickly being exposed at the hard face of the far west end of the pit, right under where the pipe had taken flight.

Recovery began as soon as the excavators bucket was out of reach of

possible contact with body parts. The pocket was full of blast rock so crystals

were not easily seen.

Careful

probing and removal of this waste material began to show more and more

specimens. The crystals once again decide that they would be completely

different than all the other chalcocites so far observed. We believe that as

much as 20% of this pocket was completely destroyed by the blast. Among what

remained were the largest specimens recovered to date,

four at over 20lbs, with up to 90% crystal coverage. Habits included

sharp single orthorhombic crystals, single sixling twins, stacked sixling twins

and unusual feather like crystals. All the specimens have the distinctive

multi-colored iridescent sheen. It

took a total of 16 hours to remove all specimen material from this pocket. The

void was big enough to sit in with room to spare, aprox. 3' wide by 4" high

by 3.5' deep. This was to be

the last pocket to be encountered at the Flambeau mine.

Top two photographs by T-BO Studios, all others by the authors.